22 Oct Six case studies and only one mission: create next-generation water resource solutions

Increasing the sustainability of water consumption by enhancing its reuse is the main aim of the WATER-MINING project. A total of 6 case studies throughout Europe will demonstrate how the recovery of secondary materials from seawater, industrial and urban wastewater is possible, including energy and water fit-for-purpose.

The water value chain includes water in three different forms – as a resource, consumable, and durable. In this context, the WATER-MINING Case Studies (CS) have been designed to correspond to each one of these forms and to address the different needs of the water users:

Water as a resource: CS 1 & 2

The development of alternative water resources is increasingly emerging as essential, with desalination and water reuse expected to play a key role in this development, especially in water-stressed regions. To help further this, WATER-MINING foresees two large-scale demonstrations at desalination plants in Lampedusa, Italy (CS1) and Almería, Spain (CS2). Both will demonstrate innovative processes to save energy and recover high-quality salts.

Water as a consumable: CS 3, 4 & 5

Urban water consumption is just a small fraction of the total human water reuse but is considered a potential alternative source of water and various materials. To address these challenges, three large-scale demonstrations are planned within WATER-MINING in Portugal (CS3), Cyprus (CS4) and Spain (CS5) aiming to recover nutrients from wastewater and achieve zero liquid discharge to minimize water consumption.

Water as a durable: CS6

Durable goods are those used for final consumption repeatedly over a period of more than one year. The development of innovative technologies is aimed at reducing the water demand of the industrial sectors. A pertinent large-scale demonstration site will be built at the site of HEXION in Rotterdam Port, the Netherlands (CS6), to recover chlorine and brine that can be reused as input for a nearby industry (Nobian).

What is the latest news regarding the WATER-MINING case studies?

In CS 1, all pilot units are under construction and will be shipped by the end of 2021. Site preparation in

Lampedusa (Italy) is in progress in order to be ready for the arrival of the single pilots and installation of the integrated seawater treatment chain. 2022 will begin and be fully dedicated to the testing of the treatment chain.

Arrival of the containers at the University of Palermo (Italy) before being shipped off to Lampedusa with the pilot plants

In CS2, a new installation has been implemented at the Plataforma Solar de Almería – PSA (Spain) to play the role of an artificial sea”. It consists of three interconnected tanks with a total volume of 300 m3 filled with real seawater. This new resource will allow experimentation to evaluate the efficiency of nanofiltration (NF) pre-treatments in the removal of divalent salts. In June 2021, a full cleaning was carried out in the MED unit to remove anytraces of scale on the heat exchangers and prepare the distillation plant for the new test campaign with real seawater. In August 2021, the MED unit was further instrumented with more temperature, pressure, level sensors and valves to have more reliable measures of its performance and improve the plant’s control systems. In October 2021, a new steam generator coupled to a field of parabolic troughcollectors was installed to extend the temperature range of the available solar thermal energy up to 220C.

The remodelling of the existing nanofiltration installation was also completed that month, incorporating new impulsion systems as well as new membranes. NF tests will begin in November 2021.

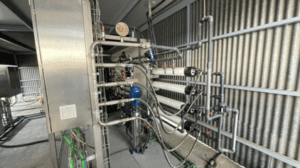

Nanofiltration technology for the removal of divalent salts installed in CS2 (Almeria, Spain).

In CS 3, a transportable pilot installation has been built to extract the valuable biopolymer Kaumera Nereda Gum from granular sewage sludge. In April 2021, RHDHV finalized the basic design of the pilot plant. Lenntech, in close collaboration with RHDHV and TU Delft are currently finalizing the detailed design, including a 3D model. In September 2021, Lenntech proudly received the first hardware for the pilot. The pilot operation will officially start in spring 2022.

The hardware of the pilot (CS3): a macerator to homogenize the granular sludge before extraction procedure, together with pumps

In CS4, all pilot units were prepared and sent from Athens (Greece) to the wastewater treatment plant in Larnaca, Cyprus. The National Technical University of Athens (NTUA) was there to organize the arrival of the units and get instructions for the operation of the BioPhree pilot that will remove and recover phosphorus from WWTP effluent.

In CS5, the first demo site located in La Llagosta (Spain) is now ready. In this case, the current wastewater treatment plant will be redesigned to demonstrate the feasibility of diverse technologies to recover phosphorus, salts, water, and energy from urban wastewater.

In CS5, the first demo site located in La Llagosta (Spain) is now ready. In this case, the current wastewater treatment plant will be redesigned to demonstrate the feasibility of diverse technologies to recover phosphorus, salts, water, and energy from urban wastewater.

First site visit by ACSA-Sorigué team members in La Llagosta WWTP, where the case-study innovation technologies will be installed (CS5)

In CS6, the assembly of the unit at the installation company is planned to be completed by the end of January 2022. The unit will then be transported to the Netherlands in spring 2022.

To learn more about the case-studies evolution, contact: info@watermining.eu