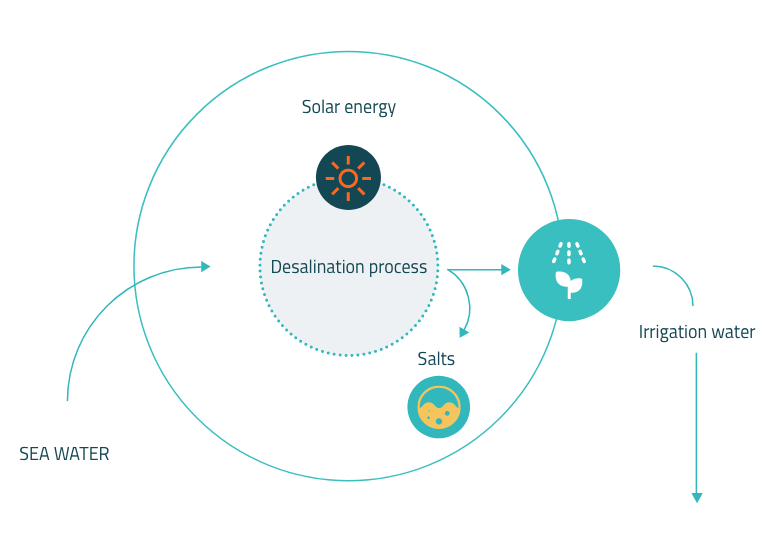

CS2 is researching the feasibility of the Zero Liquid Discharge concept from a thermal desalination process fed by seawater treated by Nanofiltration (NF) and fuelled by heat collected from solar energy. It will demonstrate a circular economy approach by extracting high value salts and elements from the water during the process.

At the case study site at the Plataforma Solar de Almer?a, a pilot-scale NF plant removes divalent ions from the seawater, which is then fed through a thermal-powered MED system to produce high quality water and brine close to saturation conditions. From the brine, researchers can collect sodium chloride (NaCL) and valuable elements that are combined with NF reject to produce mineral-rich irrigation water. The Zero Liquid Discharge approach means no environmentally damaging brines are released into the sea.